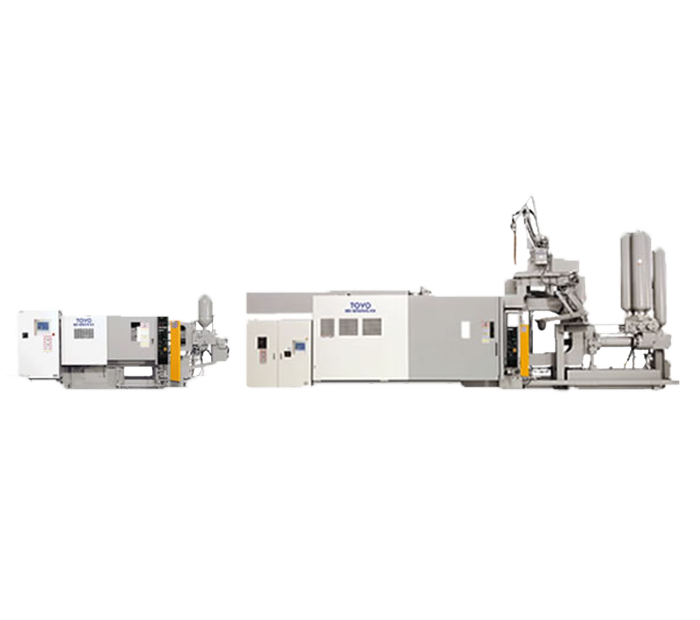

Cold Chamber

Products

Cold Chamber

Features

- Dual control: Low speed injection and intensification are controlled by electric servo motors and high speed injection is controlled by hydraulic accumulators

- Electric servo motor clamping system realizes quick and accurate control of die movements that reduce clamping impact

- Multi-step ejector speed setting promises remarkable positioning repeatability

Features

- Incorporates the latest microprocessor control system “PLCS-12” for greatly enhanced machine operability

- Automatic toggle lubricating unit for greater reliability and durability

- High performance, highly rigid frame

- Hydraulic system designed with emphasis on energy conservation and high-cycle operation

- Electro-magnetic flow control valve is standard for injection circuit (applies only to the 250-ton and larger models)