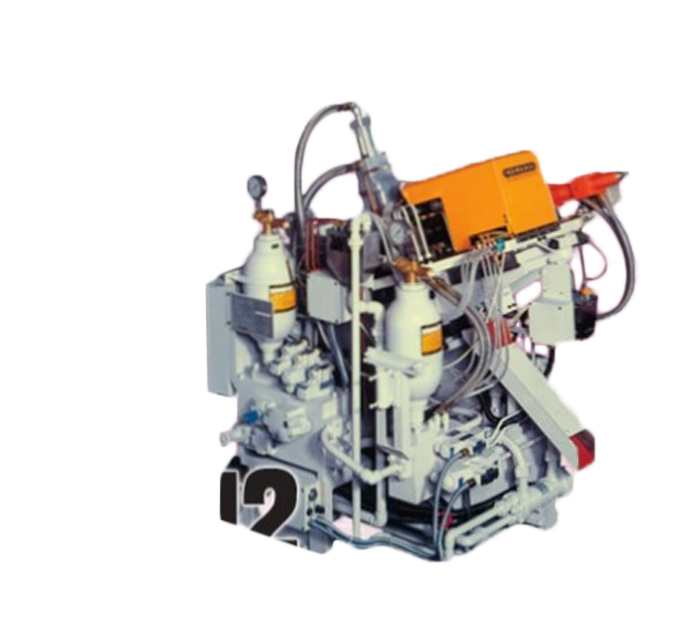

Hot Chamber

Products

Hot Chamber

Features

- Advanced magnesium hot chamber die casting machines series lineup.

- Due to excellent stability and durability, long term high cycle casting is perfectly possible.

- A multi-language touch panel display and piston type accumulator come as standard.

- Maximum injection speed 6m/sec by dry shot achieved.

Features

- Direct injection of metal at the parting line reduces areas for air entrapment resulting in better metal flow to the cavities.

- With the Parting Line Injection system, less metal is required due to the lack of a sprue, which in turn lowers re-melt cost.

- Redeced open/close times , due to the shorter stroke required with the Sprueless System.