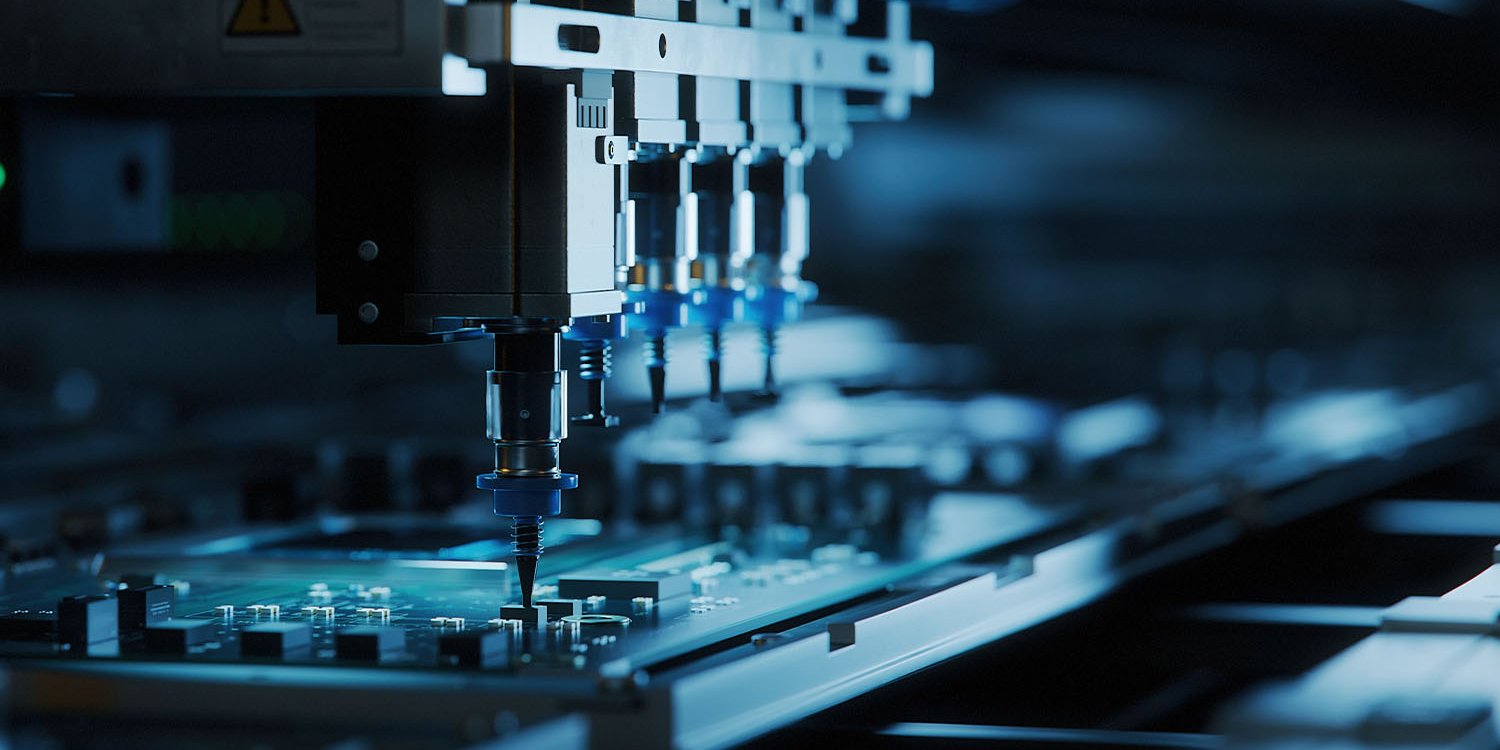

Pick & Place

Products

Pick & Place

Features

- Equipped with super multi-14-nozzle head that balances productivity and versatility

- Mounting components (up to 14 mm)in the maximum speed

- 4 Feedercartswithupto160 Feeders

- Suitable for all kinds of production

- High costperformance

Features

- High area productivity with total mounting lines

- Higher productivity and quality with placement and inspection process integration.

- Configurable modules allow flexible line setup

- Head location flexibility with plug-and-play functions.

- Comprehensive control of lines, floor and factory with system software

- Production plan support through line operation monitoring.

Features

- High area productivity with total mounting lines

- Higher productivity and quality with printing, placement and inspection process integration

- For larger boards and larger components

- PCBs up to a size of 750 × 550 mm with component range up to 150 × 25 mm

- Higher area productivity through dual lane placement (Selection spec.)

- Depending on the PCB you produce, you can select an optimal placement mode – “Independent” “Alternate” or “Hybrid”

Features

- Inline capability

- Vision system

- Assembly head

- Software modules

- Dispensers

- Custom feeders

The automatic P&P machine placeALL®610 has a modular structure and can be used for the assembly of prototypes and small series. With a wide range of handled components, ranging from chips model 01005 up to FP-parts with a pitch of 0.3 mm and BGAs, even complex tasks can be flexibly assembled.With a maximum of 208 possible feeder positions and a intelligent software, changeover times can be reduced to a minimum. The FRITSCH Company is more than30 years a successful partner in producing pick & and place machines. The production is located in Utzenhofen, Germany.Very motivated employees are working on high-tech-machines tocreate an extensive standard programand first and foremost specialist solutions.