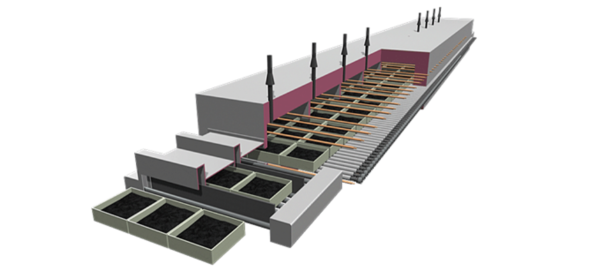

Roller Hearth Kiln (RHK):

We have experienced many projects globally for Lithium ion battery cathode and anode active materials:

- From R&D scale to pilot scale and mass production scale

- Uniform temperature distribution

- High throughput by utilizing special rollers

- Best insulation material selection to fit customers’ application

- Gas flow control

- High speed continuous firing

- Temperature : up to 1,620℃

- All ceramic materials used inside the firing chamber – No metal contamination

- Tailor made design for your materials and factory layout

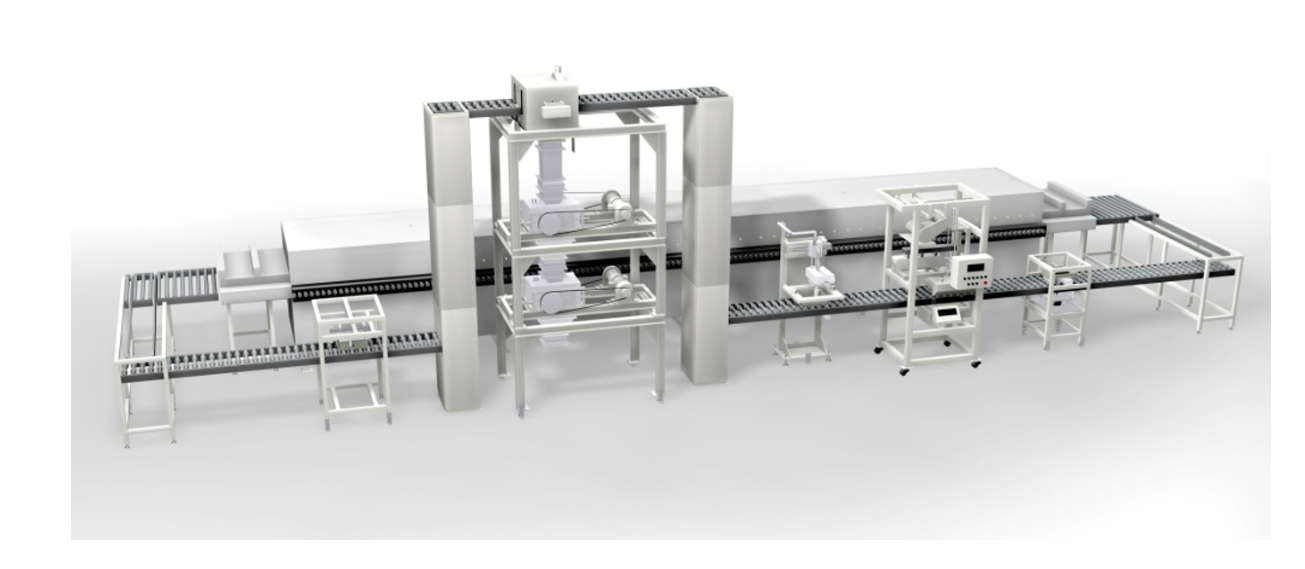

- Fully automated sagger handling system (option)

We can offer automated sagger handling systems for your production. The Lithium-ion battery market requires large amount of cathode and anode production. Our sagger handling system can cover high volume production rates with optimized footprints.