ESPEC

Products

Environmental Test Chambers

Equipped with superior temperature recovery performance capable of answering the requirements of severe test specifications, this thermal shock model offers a wide test area in a compact, slim design.

Improvement of ESPEC’s evolving lineup of constant-temperature (and humidity) chambers with capabilities and reliability supports an expanded range of testing needs in laboratories and research facilities.

Refined in operation ease and safety, as well as lower energy consumption and easier recycling, these chambers offer ESPEC’s advanced technologies. The six-model lineup includes 105- and 206-liter models available in four temperature (humidity) ranges and two sizes. All models support a single phase power supply and a wide range of applications.

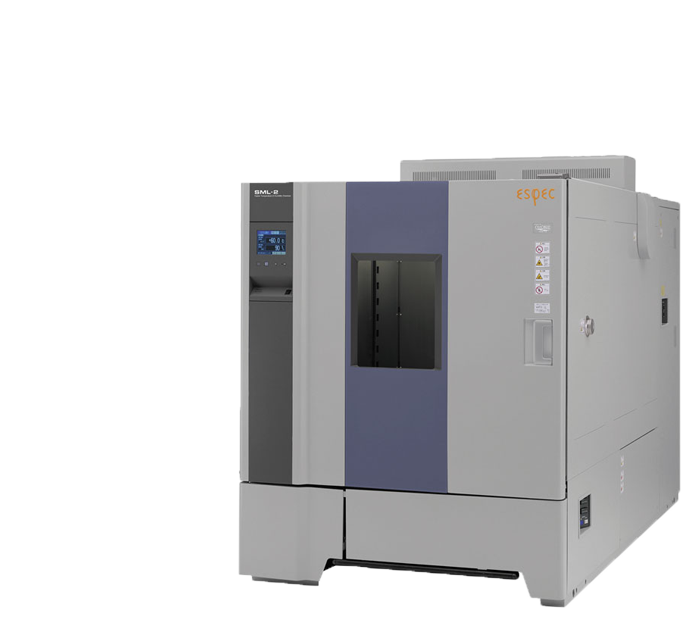

A faster temperature and humidity chamber with 1800 L capacity has been developed for reliability testing of increasingly large display devices to be used in automotive components, in car electronics systems, and more. This marks the arrival of a long-awaited large-capacity temperature and humidity chamber capable of providing a temperature change rate of 5°C/min. or more.

The chamber is packed with numerous features, including a shorter time of delivery,thanks to its standardized component units. Lower power consumption, proper height for specimen setting, and other features.

High accuracy is increasingly demanded in the pursuit of reliability in the field of electronics. “Liquid-to-liquid” type thermal shock testing is now attracting attention for its ability to impose higher thermal stress on specimens than “air-to-air” type testing, and to deliver test results quickly.

ESPEC has successfully developed next-generation liquid-to-liquid thermal shock chambers that satisfy the demand for environmental conservation and lower running costs from brine and power consumption, which have traditionally been regarded as stumbling blocks with liquid-to-liquid thermal shock chambers. ESPEC takes great pride in offering this cutting-edge chamber as a key technology in ensuring higher reliability.

The E Series walk-in type chamber is already renowned for its epoch-making power savings. Power savings achieved thanks to a wide-range refrigeration control system, an active map system, and other original control devices. Energy reduction accounts in some cases for half of the previous model consumption, due to the development of a cross output control system (patented) lowering electrical requirements of temperature & humidity operation and many other features. Energy consumption is, more than ever, an important issue to address in our line of business.

Now, the E Series capabilities are even further optimized thanks to the N-instrumentation, allying highly-accurate controllers with user-friendly interactive input system to support easy operation and network solutions. Dramatic reduction in power consumption, smoother airflow, etc. improved the temperature distribution and allowable heat load, and seal material has been designed to minimize unpleasant odors.

The E Series chamber has been brought to a new level of excellence.

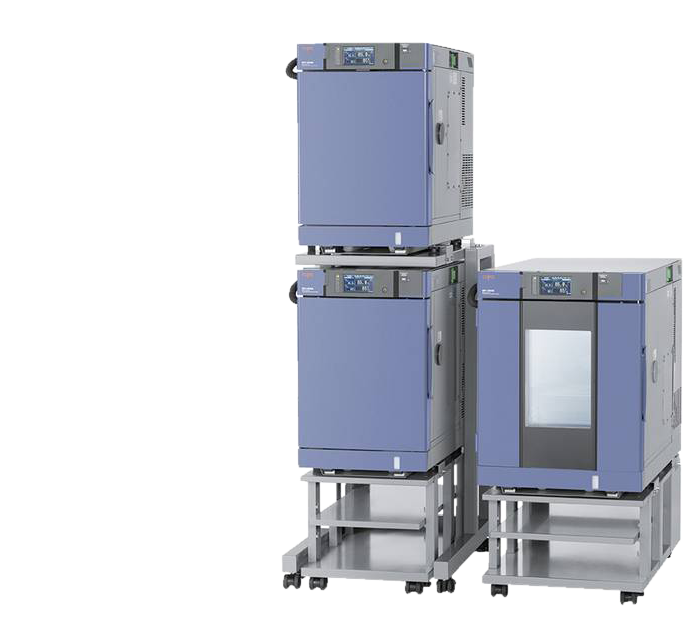

The Bench-top Type Temperature (& Humidity) Chamber Series features environmental testing performance in a compact design. Available in 20L and 60L capacities, these models offer temperature range from -20, -40, or -60°C, to +150 or +180°C, while achieving excellent performance. The chamber comes with user-friendly touch panel display, allows three-wayaccess to the chamber, and offering broader range of options for superior expandability.

The Compact Ultra Low Temperature Chamber embodies the high performance, reliability, and durability of a full-size chamber. The line-up is comprised of a total of four models. Select either the P-instrumentation for programming temperature cycling or the T-instrumentation for constant operation.

Also choose from two very wide temperature ranges that use environmentally-friendly HFC refrigerants. Select the best model for your specific application and test objectives.

The Conductor Resistance Evaluation System enables continuous measurement of resistance changes under high and low temperature cycles. Automatic measurement, data storage and processing are operated systematically with a PC. The system realizes accurate and effective contact reliability evaluations.

Today’s more sophisticated, more highly integrated semiconductor devices are the result of ever more advanced microfabrication techniques and the use of new materials. Since these techniques and materials determine device life, high precision electromigration evaluations under more rigorous accelerated stress test conditions are becoming increasingly important to developers.

The Electromigration Evaluation System offers high-precision measurement under temperature (up to 400°C) and current stresses ― the key conditions for accelerated stress testing.

Achieving reliability requires a system that delivers results quickly and reproduces environmental conditions accurately. ESPEC’s environmental stress Chamber can withstand heat loads generated by the specimen, and achieves improved temperature rate of change in an expanded temperature and humidity range.

Each chamber is also equipped with a specimen temperature control function to meet stringent testing demands typically required for automotive parts and mobile products. ESPEC offers two temperature control ranges: -75°C to +180°C or -45°C to +180°C, with or without humidity control (10 to 98%rh). These models incorporate the most desirable features in temperature and humidity chambers.

Humidity resistance evaluation tests for electronic components Customers require test results that correlate accurately to those from the field in a minimal amount of time. The Highly Accelerated Stress Test Chamber EHS Series offer high performance, functionality and ease of use, and are compliant with the international IEC60068-2-66 standard. Many convenient functions and safety features are included for bias testing.

Evaluations of electrochemical migration and insulation resistance are assuming a greater degree of importance as electronic devices are more and more miniaturized and mounted with higher density. The Ion Migration Evaluation System”allows these evaluations to be performed continuously with a high degree of accuracy and efficiency. Environmental testing has been successfully merged with measurements/evaluations.

Its rich collection of advanced features has quickly made the Platinous J Series the environmental test chamber of choice over the world. At the very top of the list of impressive Platinous J Series features is a dramatic reduction in power consumption, thanks to a new energy saving, highly reliable cooling system. The new N-instrumentation allows J Series chambers to support easy-to-use networking system.

A comprehensive selection of options along with improved installation procedures creates a new structure customizable to meet individual needs. Backed up with more than 50 years of brand history, and a foundation based on solid experience, our technology is constantly being improved and polished in order to ensure our customers unmatched reliability, performance, and safety.

Covering various applications from JEDEC and IEC test standards to screening, the Rapid-Rate Thermal Cycle Chamber is ideally suited for specimen test requiring quick changes of temperature. It is equipped with advanced technologies such as the specimen temperature control, that allows linear specimen temperature rates of change during rapid thermal cycling, or accurate temperature ramp control.

ESPEC once again dedicates its great experience in environmental test business to fully satisfy its customers.

The “Perfect Oven” epitomizes the features and performance of the ideal oven.It is a versatile product, conducting high-temperature tests, but also drying and heat treatment for production lines, with unrivaled reliability and performance. The 56 models offered by ESPEC precisely answers the various needs of our customers.

New series thermal shock chambers have been developed to improve our existing models, in terms of reliability, but also in terms of efficiency. Compared to the previous TSA series, the power consumption has been reduced of 35-50%. Energy saving is achieved thanks to the Eco operation mode; the instrumentation automatically adjusts pre-cooling and pre-heating periods and runs operations with just the necessary energy. Improvements in chamber’s reliability.

Particular emphasis was placed on removing unnecessary loads and stresses from the refrigeration system, refrigerators themselves, and the refrigeration circuit. Various measures have been implemented to anticipate troubles and enhance chamber’s reliability. Thermal stress on the specimen can differ according to its position; therefore we have further minimized variations in the temperature attainment time that influences test results.

Finally, we are accurately responding to the needs of these days by adapting our safety designs to global requirements, thanks to our experience of the market.

Two-zone thermal shock chamber ideally suited for Japanese and international test standards such as MIL, IEC or JASO . With its 100L test area, and its outstanding thermal uniformity characteristics, the TSD Thermal Shock Chamber from ESPEC can test specimens under a uniform thermal stress, and is ideally suitable for a wide range of applications, from research and development to inspection or production.

Under low pressure environment,specimens dry at lower temperature and boiling point is also lower, which reduces stress on specimens. With a wider range of applications that take advantage of the vacuum drying function, there is an increased need for the high thermal characteristics of a vacuum drier as well as for improved production efficiency and reduced power consumption. To meet this demand, ESPEC upgraded the vacuum oven VAC Series. The new instrumentation achieves excellent usability and advanced functionality. For example, program operation can be selected for precise, automated control of pressure and temperature.

A 20 to 40% power savings is achieved thanks to improved air tightness and sealing capacity of the chamber. A variety of options are available including the absolute pressure sensor. Furthermore, extensive safety designs complying to globalization trend have been added to meet the CE certification requirements. Based on the achieved temperature and pressure control capabilities for testing equipment, in which high reliability and high accuracy are expected, ESPEC further refines the capacities required for manufacturing equipment.

ESPEC’s Clean Ovens are used extensively for heat treatment of specimens and drying components in stringent clean air requirements of Class 5 cleanliness. A space-saving upright design, and a large LED display for improved visibility are some of the user-friendly features. Eight models to choose from, including high performance models which ensure automated operation and dedicated cleanliness even throughout temperature heat-up or cooling procedures.